CNC (Computer Numerical Controlled) machines have revolutionized the industrial sector when it comes to manufacturing. As the name suggests, CNC machines have specific instructions in code that help them cut metal and other rigid materials to an exact degree. If you are an aspiring businessman trying your luck in the manufacturing industry, we can help you familiarize yourself with some of the most common CNC machinery for sale that you can get your hands on.

This blog post will look at some of the most regularly used CNC machines.

5 Basic Types of CNC Machinery for Sale:

Industrial machine tools are sensitive mechanical devices that can go out of calibration if not used correctly. They require professional help to fix, so it’s always a great idea to get training to use them properly.

CNC turning and lathe machines:

CNC turning machines and lathes use a rotating mechanism to spin hard materials like metal, while a cutting tool is aligned linearly to cut precisely around the circumference. That results in accurate rounds with perfect diameters consistent across the board. The machine can also cut holes of fixed radius in items like nuts and bolts. These machines are precise down to the thousandth of a millimeter and require specific instructions to be fed to achieve this precision level.

Next up is laser machines.

Laser Machines:

Laser machines use light amplification through stimulated emission of radiation, which, in easier terms, is just focused, intense light beams used to cut metal. Thanks to the laser’s precision, the beam melts and vaporizes the metal, forming a uniform and clean-cut. The pointed laser is also used to carve metals and can be used for applications like setting the company name or logo into a metal screwdriver.

A reliable CNC machine company like Flint Machine Tools makes sure you have the proper know-how to operate a technical machine like this.

CNC Plasma Cutting Machine:

Like most other CNC machines, plasma machines are also used for cutting. However, they do it using a high-energy plasma torch which is electronically ionized gas. It means the atoms in the gas are electrically charged, enabling the torch to reach 50,000 degrees Fahrenheit. The torch melts through metal like butter, and because it is focused, the cut is immaculate and precise.

Since the torch uses electronically charged gas, the material being cut should be electrically conductive, for example, metal or steel. If you use it to cut wood, it will simply catch on fire.

CNC Electrical Discharge Machine:

A CNC EDM uses electrical discharge to mold hard materials into the desired shape. Also known as spark erosion, you place the material under a cathode that produces an electrical discharge, heating the material to 21,000 degrees Fahrenheit. Once the metal is cut, it is flushed with fluids to get the desired shape.

EDM is used to create neat small holes or angles in metal. There are a lot of other functions it can perform as well, like creating slots and tapers, and it is used for hard materials that can be tough to shape.

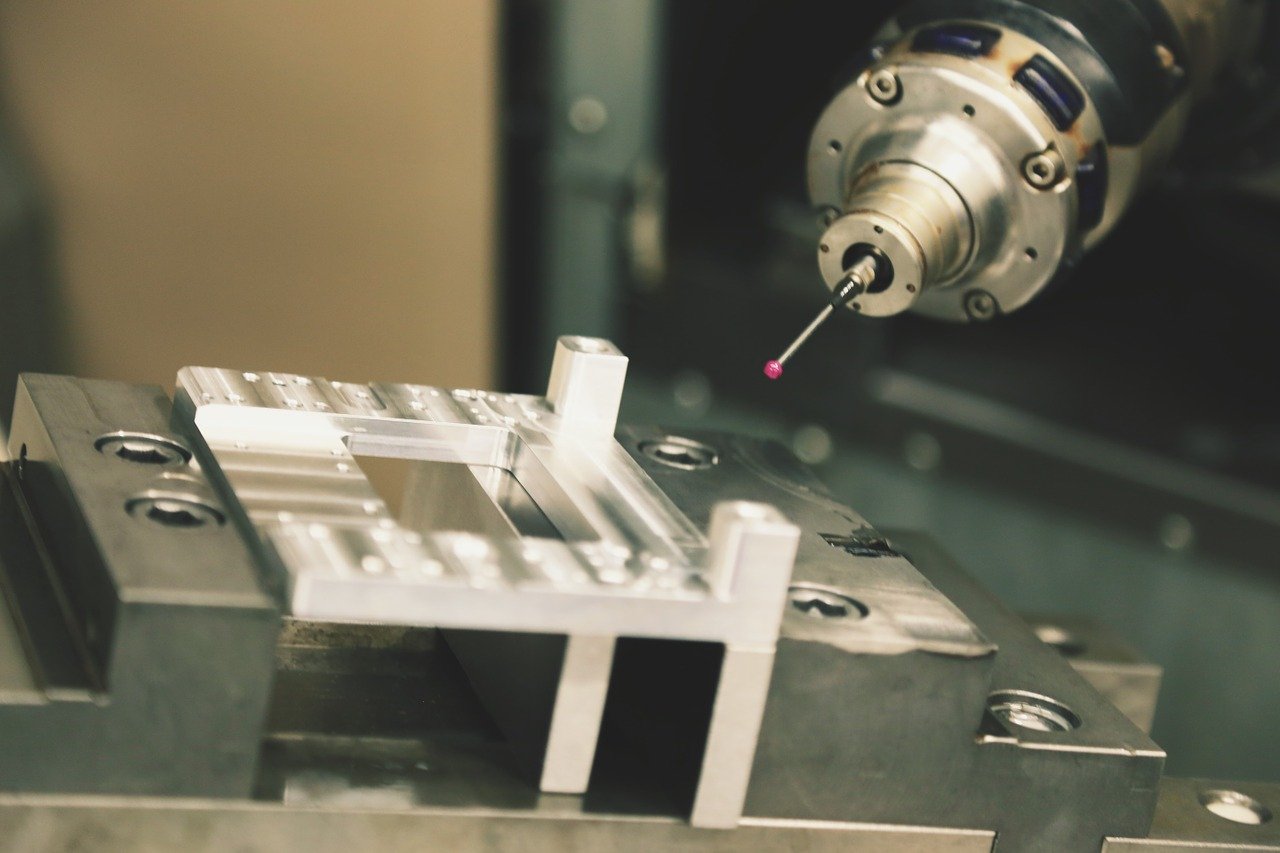

CNC Milling Machine:

A CNC milling machine rotates cutting tools around your material of choice to create shapes like squares and rectangles with features like cavities and slots in them. Holding the working material in place enables the machine to apply force to mold the metal in the exact shape you want.

That concludes the list of some of the most common CNC machinery usually for sale; you can grab them to get started in the manufacturing business. If used responsibly and maintained well, these machines can produce better results than manual labor. If you like your products to be consistent and high quality, CNC machines are the way to go!

For further information, visit the FAQs section below.

FAQs:

What can CNC machines be used for?

The primary function of a CNC machine is to take the manual labor out of the equation when it comes to manufacturing products. It is used to mold complex substances like metal to get precise shapes and sizes.

What is ATC in a CNC machine?

An Automatic Tool Changer is used with CNC machines to improve its capacity for tool carrying. It can also help with enhancing CNC production.

What is meant by the canned cycle in CNC?

A combination of machine locomotion that helps perform operations like milling, tapping, drilling, and boring is called a canned cycle.